Production Management System

"ProcessWatcher", a production management system developed based on ERPWatcher, is a manufacturing system that handles production planning, production results, purchase orders, loading/shipping, raw material inventory, etc.

Are you having trouble with poor production control?

Production control refers to the management of production activities so that production plans can be executed, and the control to be taken if problems occur in the progress of the plan. The management of production activities can be broadly divided into three areas: "progress management," "actual product management," and "surplus capacity management." If there is a discrepancy between the information obtained from management and the plan, it becomes necessary to take immediate measures or to carefully review the production plan.

If production control doesn't work...

- A lot of time is spent on production planning

- Urgent orders mean plans change frequently

- On-site work efficiency is poor, with a lot of wasted time waiting and overtime.

- The books and actual inventory do not match, making it difficult to know where and how much work-in-progress inventory is held.

- Material shortages occur, and inventory levels of raw materials, work in progress, and finished products increase, resulting in increased waste and delays.

- I don't know where to start

- Frequent delays in delivery and inability to respond immediately to delivery date inquiries

ProcessWatcher will solve your production control problems.

By introducing ProcessWatcher, you can improve the efficiency of the "progress management," "actual product management," and "surplus capacity management" that are the management of production activities, and provide strong support for production control.

You can compare production requirements with equipment capacity.

Can be calculated backwards from the delivery date and the number of days required to complete the process

The latest production start date can be calculated, making it easy to plan schedules even for urgent orders.

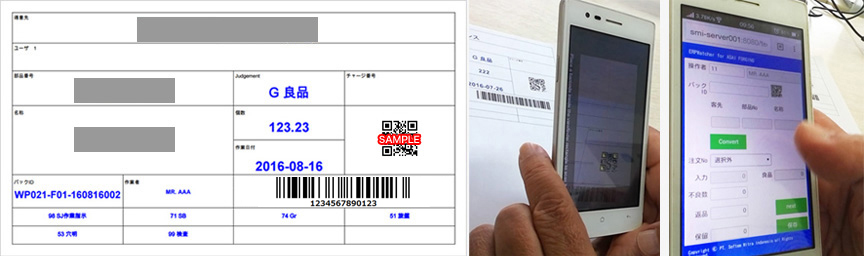

Work results can be easily entered on-site

Using the smartphone version of the performance input screen, you can input data from your smartphone anytime, anywhere.

You can also create and manage work-in-progress labeling with QR codes, and by linking it to your smartphone camera and reading the QR codes, you can manage your inventory more smoothly.

QR Code is a registered trademark of DENSO WAVE Inc.

Know where things are in real time

Since finished goods inventory and work-in-process inventory can be assigned to each order, problems such as the ledger not matching the actual inventory can be prevented.

You can check in advance whether there are any shortages of materials

You can refer to the work-in-process inventory and understand the work priority.

Know the shipping date for each order and respond immediately to delivery date inquiries